Customer Story: Innovative , Boundless Smart Manufacturing

2024-08-26

In the vast blue ocean of smart manufacturing, Estun Automation, a leader in robotics and automation, continuously drives industrial upgrades with its profound technical expertise and spirit of innovation. As a standout in the industrial machine tool sector, Haitian Precision’s high-precision and highly stable equipment is well recognized in the industry. When Estun met Haitian Precision, a deep collaboration in smart manufacturing began, creating a tale of mutual cooperation and integration.

01 Increasingly Seamless Collaboration

Established in 1993, Nanjing Estun Automation (Estun) adheres to an open, innovative, and striving business philosophy, consistently focusing on independent R&D for core technologies. From core components to motion control, and further to robotics and digital intelligent solutions, Estun remains at the forefront of the industry, providing customers with comprehensive smart manufacturing services. Behind this is Estun’s relentless pursuit of manufacturing equipment and stringent quality control over its products.

Encountered with growing production capacity demands, Estun decided to upgrade its overall smart factory solutions by introducing a more efficient Flexible Manufacturing System (FMS). After extensive research and in-depth discussions, Haitian Precision stood out among numerous domestic and international competitors, securing a strategic partnership with Estun due to the high precision of its machine tools and comprehensive technical support.

As the equipment gradually arrived and was installed and debugged, the teams from both sides worked closely to continuously optimize production processes, ensuring each step achieved its best state. Since its launch at the beginning of the year, Haitian Precision’s FMS has been running stably, with production steadily increasing, proving the correctness of Estun’s choice.

02 A Dual Leap in Efficiency and Quality

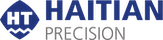

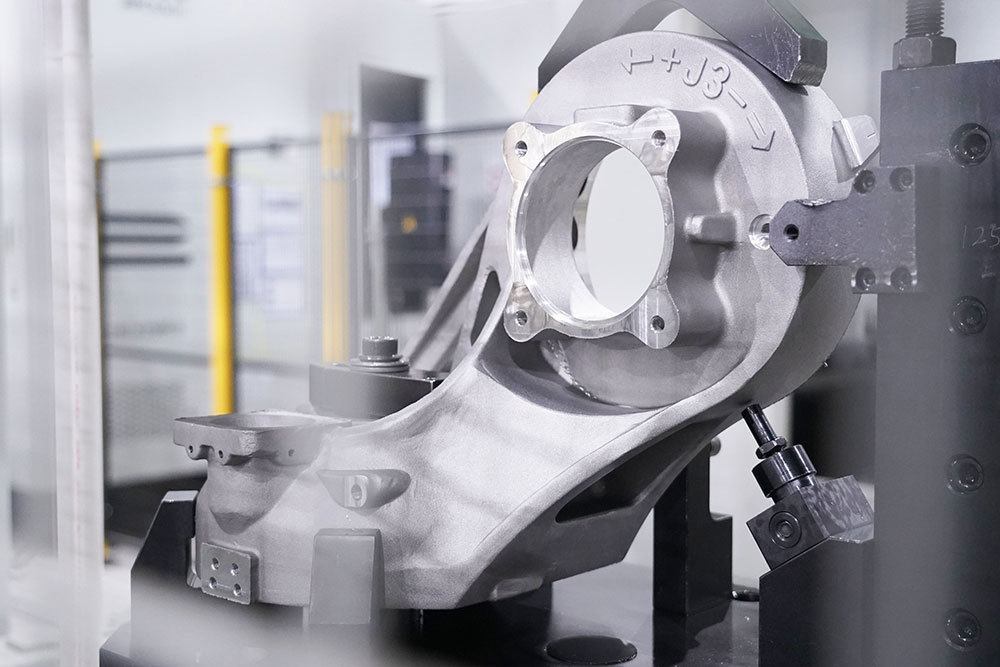

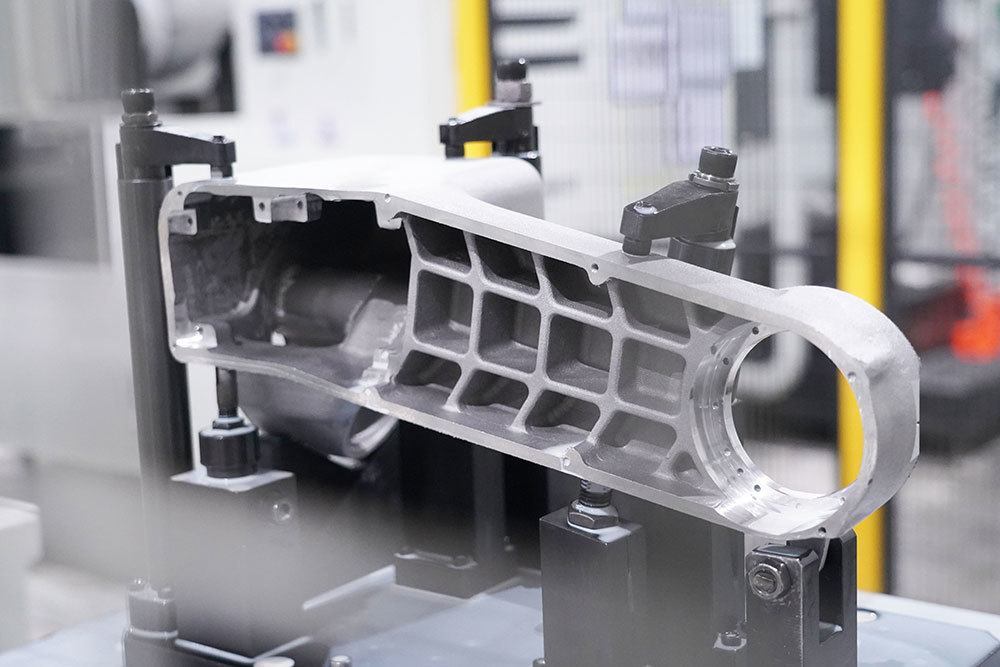

Haitian Precision’s FMS focuses on the precision machining of motor housings, drive casings, robot bases, and arm castings, bringing significant efficiency improvements to Estun. The introduction of FMS allows for zero-changeover and zero-switching when processing various complex robot components, significantly enhancing equipment utilization. At the same time, Haitian Precision’s high-precision machine tools ensure that the machining accuracy meets or even exceeds expectations, laying a solid foundation for Estun’s product quality.

Haitian Precision’s FMS has effectively improved Estun’s production and processing model. In terms of manpower, what once required one person per machine now only needs one to two people to manage six machine tools in continuous operation, greatly increasing processing efficiency. Additionally, the flexible line’s built-in tool breakage monitoring function can automatically switch tools using sister tools, protecting tool life and reducing downtime. The multiple sets of process programming within a single machine can automatically select processing based on the loaded workpieces, offering distinct advantages over traditional gantry lines or robots in the production of small batches of diverse products. The high-precision horizontal machining centers from Haitian Precision also demonstrate outstanding performance, running stably and meeting both high-load cutting and high-speed processing needs, fully maximizing efficiency.

Assistant to the President of Estun: Li Wenlong

“FMS has further enhanced production operatingrates, reaching a high level of 90%-95%. The preci-sion is also spot-on, with daily part accuracy within10 microns, fully meeting production requirements.”

03 Comprehensive Support and Assurance

Estun highly praises Haitian Precision’s machineries, believing that it matches or even surpasses foreign brands in performance. Haitian Precision’s technical support and after-sales service have provided Estun with unprecedented convenience and peace of mind. The technical personnel at Haitian Precision are not only professional and responsible but also proactively analyze and eliminate potential risks after resolving issues, preparing preemptive plans to ensure the continuous and stable operation of the production line.

Haitian Precision understands the importance of after-sales service, from equipment installation and debugging to daily maintenance. Their technical application personnel are always by their side, ensuring the equipment is always in its best state. Additionally, Haitian Precision has provided customized services tailored to Estun’s production needs for robot part machining, further improving production efficiency and machining accuracy.

Chief Engineer of Estun: Zhang Haicheng

“Haitian Precision has given Estun strong supportin technology and services, and their guidance hasbeen of great help to our equipment staff.”

As emerging industries continue to seek both “new” in “quality”, Estun and Haitian Precision have formed complementary advantages in the industrial chain, bringing about mutual understanding and synergy. Intelligent matching allows the machine tool’s performance to be maximized, while the machine tool ensures efficient and stable production of parts. High-end CNC machine tools and smart equipment are setting a new benchmark for the industry, opening up new boundaries in smart manufacturing. The story of Estun and Haitian Precision in this manufacturing revolution continues…